What makes supply chains smarter today – data or the engineers behind it? Automation systems work efficiently because data engineers design and guide every step. They set up the systems, write the algorithms, and ensure the process runs as planned. If you’ve ever wondered how your online order arrives so quickly, it’s a result of their efforts behind the scenes.

Yet, while automation and AI are transforming supply chains, building systems as adaptive as the industries they serve is more complex than adding some tech and moving on. The real difference-maker? People who can make machines work smarter – data engineers who understand the nuances of AI, automation, and logistics.

But what exactly sets exceptional data engineers apart regarding supply chain innovation? Is it their ability to craft seamless integrations or the foresight to design AI systems that adapt to shifting demands? Read on to learn the competencies that define standout professionals in this field and how they’re driving change in supply chain processes today.

Did you notice how the shelves in your favorite store rarely seem empty anymore? That’s not a coincidence – it’s technology doing its job. From predicting demand spikes to rerouting deliveries in real-time, AI and automation are taking supply chains from reactive to proactive. The result? Smarter systems, faster solutions, and fewer headaches for businesses and customers alike.

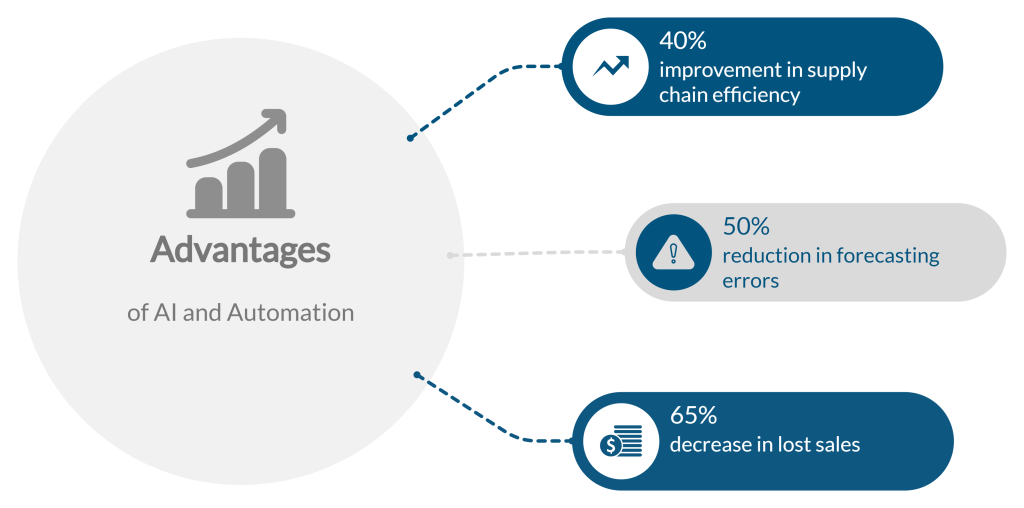

In fact, according to data by Hypersonix, AI improves supply chain efficiency by 40% through data processing, trend prediction, and task automation. It’s also responsible for a 50% reduction in forecasting errors, making those “out-of-stock” signs less frequent. On top of that, companies using AI report a 65% drop in lost sales, proving that more innovative supply chains aren’t just about speed but resilience.

Let’s now look into ways which AI and automation are reshaping supply chains:

Why do some stores always have what you need while others miss the mark? AI-powered systems track sales trends, seasonal patterns, and regional preferences to keep shelves stocked without overloading warehouses. For example, a grocery chain might use AI to predict the demand for specific fruits during holidays, ensuring no surplus of watermelons in December.

Guessing doesn’t cut it when it comes to meeting customer expectations. AI uses historical data and real-time market insights to forecast demand accurately. For instance, a clothing retailer can predict which styles will sell faster during back-to-school season, helping them avoid overproduction or understocking.

How do delivery drivers navigate unpredictable traffic or last-minute weather changes? Automated systems analyze traffic data, weather patterns, and delivery schedules to optimize routes. This helps ensure your package arrives on time, even in challenging conditions like a snowstorm.

Mistakes in manufacturing don’t just lead to waste – they cost hefty time and money. AI-powered tools can identify defects during production faster than any human eye. For example, a factory producing car parts might use machine vision to detect tiny cracks or irregularities, ensuring only top-quality items move forward.

What happens when a shipment gets delayed at the last minute? AI systems can analyze the problem, find alternate suppliers, and adjust delivery schedules almost instantly. For example, if a major port closure delays goods, an AI-driven platform can reroute shipments through other ports before delays spiral out of control.

When you think of supply chains, you probably picture trucks, warehouses, and conveyor belts. But what ties all those moving parts together? Data engineers. These professionals ensure every decision, from production to delivery – is backed by accurate, actionable information. Without them, supply chains would be less efficient and far more chaotic.

Supply chains rely on constant data flow to keep operations running smoothly. Data engineers design and maintain pipelines that collect, process, and deliver information from multiple sources, like inventory systems or sales platforms. For instance, they might create a system that tracks raw material shipments in real time, ensuring manufacturers know precisely when to prepare for production.

Data in supply chains isn’t static; instead, it grows as operations expand. Data engineers design databases that can handle increasing volumes of information without slowing down. For example, a logistics company managing thousands of shipments daily needs a database that won’t crumble when the volume doubles during the holiday season.

Decisions are only as good as the data behind them. Data engineers implement checks to ensure information is accurate and up-to-date. For example, they might develop a system that flags discrepancies between warehouse inventory counts and digital records, helping to prevent costly errors.

AI might grab headlines, but data engineers make those systems work in practice. They ensure AI tools are fed with clean, structured data to deliver reliable outputs. For example, they might set up integrations between sales platforms and an AI forecasting tool, enabling real-time demand predictions.

Nobody wants to spend hours on repetitive tasks. Data engineers develop automated solutions that reduce manual work in supply chains. For example, they might create a script automatically updating inventory records when new shipments are received, saving warehouse staff time and effort.

Supply chains move fast, and so does the data. Data engineers set up systems that provide real-time analytics, helping teams make informed decisions on the fly. For instance, a retailer might use these analytics to redirect shipments to locations with higher-than-expected demand.

Equipment downtime can be expensive. Data engineers help set up systems that predict when machines might fail using data from sensors and historical records. For example, a factory might use these systems to schedule maintenance for its assembly line before an unexpected breakdown occurs.

Raw data isn’t valid until it’s visualized. Data engineers create dashboards tailored to supply chain needs, giving stakeholders a clear view of operations. For instance, a manager might use a dashboard to monitor shipping delays and adjust schedules in real-time.

Supply chain data includes sensitive information, from pricing to customer details. Data engineers implement security measures to protect this information from breaches. For example, they might encrypt data transfers between suppliers and warehouses to prevent unauthorized access.

Supply chains involve many moving parts, and data engineers work across teams to ensure everything aligns. They might collaborate with procurement teams to improve supplier data accuracy or work with IT teams to integrate new systems. For example, a data engineer ensures the transition is seamless during a software upgrade without disrupting operations.

Building an AI-powered supply chain relies on more than advanced tools or algorithms – it depends on the people who make them work. Data engineers play a significant role, turning raw data into insights that drive automation and smarter decisions. However, not all data engineers are ready for the challenges of AI-driven supply chains. How do you spot the ones who can handle the unique demands of this field?

Here are the skills to look for when hiring data engineers for AI and automation-powered supply chains:

A data engineer who understands data architecture can streamline complex systems into seamless workflows. They know how to design frameworks that handle structured and unstructured data, which is critical in supply chains where inputs range from sales forecasts to IoT sensor readings. For instance, they might build a pipeline integrating shipment data from multiple carriers into a single, easy-to-use dashboard. This expertise is necessary for inefficiencies and bottlenecks to be improved.

The correct data engineer excels in Python and SQL. These languages are needed for automating processes, creating algorithms, and managing massive datasets. For example, an engineer might use Python to write a script that analyzes sales patterns and suggests stock replenishments. Their ability to code effectively makes AI and automation more actionable.

While data engineers don’t need to be full-fledged machine learning experts, a solid understanding of ML concepts is a big plus. This allows them to work seamlessly with data scientists and ensure models are trained on clean, structured data. For example, they might set up a system that feeds historical sales data into a machine-learning model to forecast demand spikes. It’s all about making sure the AI performs accurately and reliably.

Modern supply chains rely on cloud platforms to manage and scale their operations. A skilled data engineer knows their way around platforms like AWS, Azure, or Google Cloud, leveraging these tools for data storage and processing. For instance, they could deploy a real-time analytics tool on the cloud to track inventory across global warehouses. This knowledge makes handling the dynamic nature of AI-driven supply chains easier.

Raw numbers don’t make decisions – people do. That’s why a sound data engineer should be adept at visualizing data in ways that are easy to understand. Whether creating dashboards in Tableau or building custom reports, these skills help stakeholders see the bigger picture. For example, they might present data on shipping delays in a way that highlights the root cause, making it easier for teams to act quickly.

Supply chains come with their fair share of unexpected twists, and a data engineer with a proactive mindset is invaluable. They’re the ones who can troubleshoot errors in a pipeline or optimize systems to handle fluctuating workloads. For instance, if a sudden spike in demand causes a processing bottleneck, a resourceful engineer can tweak the system to keep things running smoothly. It’s about anticipating issues and finding innovative, data-driven solutions.

If your supply chain is changing and continuing to advance with AI and automation, having the right data engineers on your team makes all the difference. How do you spot the right talent? Focus on those who combine technical expertise with curiosity to solve real-world problems. Investing time in identifying these skills can set your business up for smoother, more intelligent operations.

Are you looking for data engineers who can lift your AI-driven supply chain? At Talentguy.io, we specialize in connecting businesses like yours with top-tier talent in data engineering and automation. Our team is dedicated to helping you build a workforce equipped to handle the demands of modern supply chains. Reach out today to discuss how we can find the perfect match for your team.